Using hammering motion armature bar will tap the needle with a spring to allow the artist to draw tattoos. Browse discover thousands of brands.

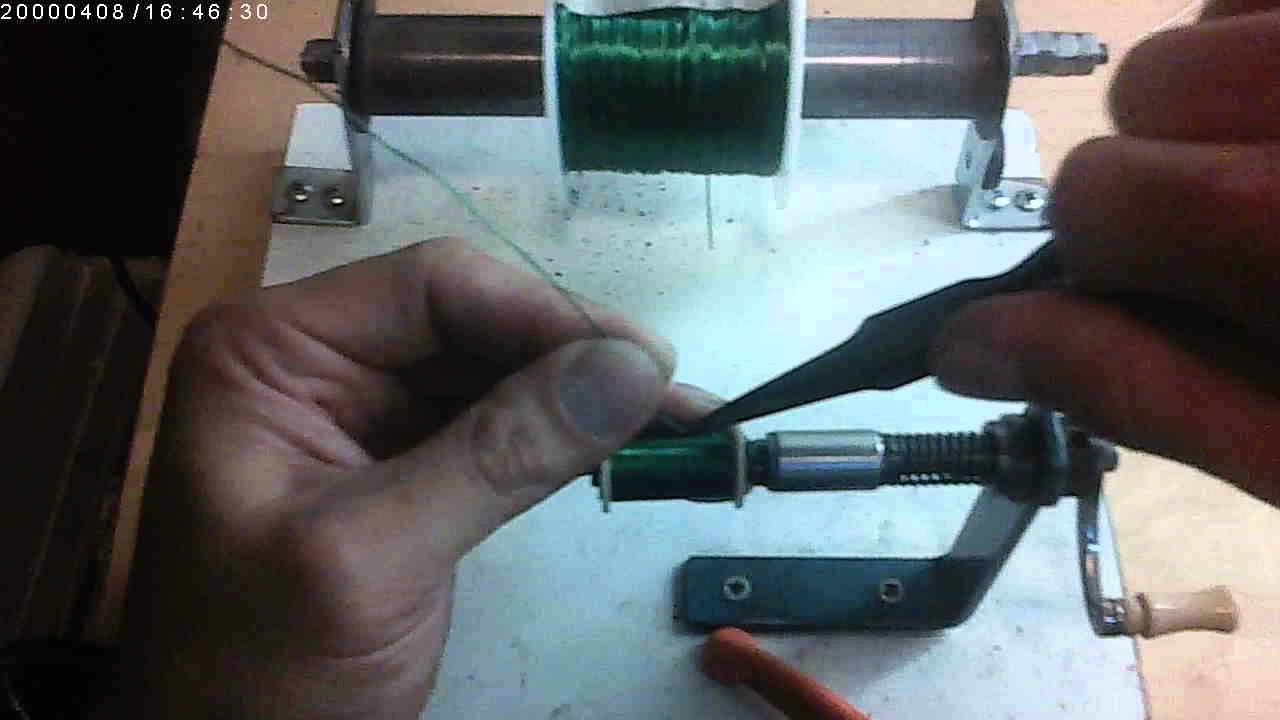

Alex Kuo Of Akirons Hand Wound Coils Tattoo Machine Parts Youtube

The armature bar gets attracted to the magnet.

. Also having a tattoo of your own will show your clients that you can empathize with the experience which will help put them at ease. Feed the wire through one of the holes leaving at least three inches of wire sticking out for later soldering. Attach the clip cord to your machine and turn on your power pack.

Since then the electromagnetic coil has gone through many changes and is used in a number of day to day operations one of which being the tattoo machine. Usually tattoo artists will use 8 coils machines to draw outlines of tattoos but you are suggested to get 10 wrap coils which works pretty better for both shading and lining. Be careful to only touch the contact screw by the rubber tip or it will shock you.

WORKINGS OF A TATTOO MACHINE. Joker Tattoo Supply stocks and ships professional quality tattoo machine coils worldwide. Black 6 Wrap Coil Set T-Top Coil Core 516 x 1 14 33Uf 50V Capacitor.

Wrap the wire around the bobbin being careful to. Cut the 2 x 4 into two eight-inch pieces. Order your tattoo machine coils today and enjoy our fast.

Wrap coils Electromagnetic current will pass through star-shaped coils once you attach your machine with a power supply. WORKINGS OF A TATTOO MACHINE. Pay attention to make the coils tight and.

Stand the 2 x 4s upright six inches from each end of the 2 x 6. First you can keep up the widest end of plastic bobbin with one hand and make the insulated copper wire wrapped around it 2 or 3 three times by your the other hand. Read customer reviews find best sellers.

Mark around their perimeter with a pencil. On the other hand an 8 wrap coil isOnce your tattoo has been outlined your tattoo artist will use a shading needle to color fill or shade inside the outline of the. Holding the machine firmly in your tefl hand by the frame slowly turn the contact screw down clockwise to meet the contact point on the front spring.

The wires exiting the coil assembly must be insulated with a heat shrink before they are connected one coil to the other and wires to terminals. Things can be done in a much easier way. Then wrap the wire around the bobbin.

The bottom of the shaft is the side with the treaded hole. It will trigger an armature bar that will start the release and draw mechanism. Pay attention to make the coils tight and massive when.

The coils become electric magnets. Remember to leave about 4 inches of wire sticking out for the next steps. Because of the proximity of the wires exiting the bottom of the coil bobbins to the yoke or base of the frame it is important to make sure the wires are totally insulated all the way to the plastic.

Wrap the insulated copper wire two or three times around the wide end with your other hand leaving about 4 inches of wire sticking out. Get a tattoo yourself. These will serve as the upright supports for the coil winding machine.

This will serve as the base for the coil-winding machine. Make two small holes in the bottom of your round covering disk. In order to make the coils work as a team the coils must be connected to each other by a shared base made out of magnetic material preferably the same material the coils cores and armature bar are made from because these are all part of the magnetic system.

Ok lets see how to wrap your own tattoo coils. First you can hold the widest end of plastic bobbin with one hand and make the insulated copper wire wrapped around it 2 or 3 three times by your the other hand. Heres a better look at wrapping tattoo machine coilsThis video is for demonstration purp and I do not infringe on any copyright lawsIf you would like to s.

Then wrap the wire around the bobbin. A steel or iron frame will serve this purpose but any frame made from any non. Ok lets see how to wrap your own tattoo coils.

Ive seen someone wrap tattoo coils all by his bare hands but to get it done by a coil-winding machine will be a better choice. This will give you first hand experience as to the procedure atmosphere and techniques from other tattooists. Hold the plastic bobbin by the widest end with one hand.

Remember to leave about 4 inches of wire sticking out for the next steps. When the bar springs up the points make contact and the circuit starts again coils become magnetized. When the circuit breaks the bar springs back up.

Cut the 2 x 6 board to a length of three feet. Thread a screw into your coil shaft and put it in a multi-speed electric drill. The needles move up.

All our coils are hand wound in house from the perfectly machined cores and the overwhelmingly strong phenolic end caps to the highest quality magnet wire money can buy our coils are truly.

17 Coil Winder Ideas Winder Coil Guitar Pickups

Awg 24 Gauge Copper Wire For Tattoo Coils Tattoo Machines

Tattoo Machine Building How To Coil Wrap And Cover Youtube

Tattoo Nerd Coil Tattoo Machines 101

Awg 24 Gauge Copper Wire For Tattoo Coils Tattoo Machines

Tattoo Machine Building Coil Wrap Youtube

Steel Wool Inside The Tattoo Coils Tattooing Basics Tattoo Magic

0 comments

Post a Comment